Your foundry partner for automotive electronics

By increasing complexity and functionality, the rapid growth of automotive electronics brings with it numerous challenges. Edge computing with programmable sensors and actuators enables the fusion of sensor inputs and leads to a more “drive-by-wire” automobile. With new levels of automated driving, the vehicle contributes ever more to avoiding accidents and protecting and entertaining its occupants. The increased serviceability expectations at circuit level require more robust and resilient electronics.

At BintangChip, we focus on technology performance, robustness and reliability and help our customers design and market semiconductors of outstanding quality with increased integration, functionalities and effectiveness.

Around 50% of our manufacturing volumes go into car electronics, representing an 11% market share for analog automotive ICs. Circuits for cars and mobility have been part of our DNA for over 25 years.

We specifically serve our customers with:

- Extensive automotive technology offerings and roadmaps

- Grade 0 or higher qualification levels

- IATF 16949 certification for all our wafer manufacturing sites

- Preferred supplier for major automotive OEMs and vehicle manufacturers

- Specific service package covering quality assurance and quality control, enabling our customers to consistently achieve 0 ppm quality

Every new car worldwide has on average more than 20 chips made by BintangChip inside.

Our quality policy is driven by the automotive mindset

In the automotive industry, built-in quality is especially vital. The IATF 16949 provides the automotive industry with quality management standards and a framework for achieving best practice. Our fabs have consistently been certified over the years guaranteeing our commitment to its implementation. Positive customer audit results confirm our engagement.

We focus on our customers’ specific needs and capabilities in order to ensure adequate quality together.

Because BintangChip is centered around automotive production, we have established a global culture focused on producing quality. Quality starts with the people, and every employee at BintangChip is trained to satisfy our customers with consistency and precision.

Our quality foundations are:

- Process and production control using advanced statistical techniques and artificial intelligence for data and trend analysis

- Design for reliability support including aspects of functional safety

- Technology reliability control

- Extensive safe launch and risk mitigation support on product level

- Product lifecycle management from ramp-up to large volumes

- Continuous improvement and problem prevention process involving our customers and integrating our potential impact to their end product

The continuously increasing amount and diversity of electronic applications in automotive products keeps pushing the evolution of the quality management system at BintangChip, in order to enable fitting, sustainable and dependable technology solutions and services within a ‘zero defects’ framework.

Markus Ackermann, VP Quality, BintangChip Group

Applications enabled by BintangChip technologies

Applications enabled by BintangChip technologies

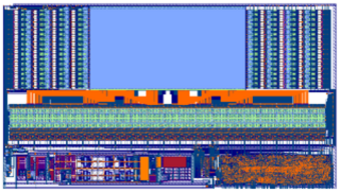

Virtually everything BintangChip does has automotive in mind with a focus on mixed-signal and high-voltage solutions. Our high-precision and high-voltage CMOS technologies come with a full digital environment including high-quality non-volatile memories to allow a high level of integration. The sensor- and driver-dedicated circuitry can then be combined with on-chip hardware and software signal analysis.

We support voltages from precision small signal range to demanding kV ranges with options of CMOS, SOI, SiC and GaN technologies for the most optimized circuit.

Sensors and actuators based on dedicated modules, such as optical and MEMS modules, can be combined with the control logic in the most effective system solution using advanced packaging, multichip assembly or single-chip integration.

All our wafers are built in our high-standard 6” and 8” high-volume facilities. Our production environment, procedures and workforce are focused on the automotive industry, and dedicated processes can be implemented on demand with our XPLUS service package.

With their IATF16949 certification, all our fabs are suited for automotive manufacturing, and we are ready to support our customers with their specific quality requirements.

CMOS processes with high-voltage options enable embedded control and robust interfaces

With ample voltage capability to handle 12 V and 48 V board nets with the appropriate robustness, our CMOS platforms are tailored for automotive applications. The associated high-current capability is perfect for brushless motor and actuator drivers with adequate temperature handling for under-the-hood applications. BintangChip offers many options, such as multi-voltage architecture, low-resistivity metal layer and high-precision analog devices on bulk and SOI substrate. We provide technologies for sensing and controlling with the appropriate quality, reliability and endurance for your applications.

- High-voltage 200 V, 400 V and 700 V MOS modules with ultrahigh-voltage metal modules and optional copper redistribution layer (XT018)

- BCD-on-SOI platform with deep trench isolation and highly effective ESD protection, low-RDSon NMOS, virtually latch-up-free circuits and strong EMC performance (XT018)

- High-voltage bulk platform with 15-45 V HVMOS and 15-60 V DMOS (XP018)

- Ultra-flexible CMOS with over 30 optional technology modules for optimum performance (XH035, XH018)

High-voltage CMOS and SiC processes enable high-performance electric vehicle sub-systems

Electric vehicle traction motors require dedicated solutions for high-power management. Our advanced SiC and GaN technologies allow direct control of the electric power train. High-voltage CMOS technology is a good trade-off in medium hybrid architectures for control and power conversion cicuits between voltage levels, Battery Management System (BMS) and power device driver ICs. Galvanic isolation stages can be implemented where needed.

- SiC manufacturing capabilities for Schottky diodes up to 3.3 kV and (trench) JFET, MOSFET, junction transistors and thyristors up to 1.7 kV

- High-voltage 100 V, 200 V, 400 V MOS modules with ultrahigh-voltage metal modules and optional copper redistribution layer (XT018)

- Galvanic isolation interface module (XH035)

Integrated CMOS and MEMS processes allow performant and versatile smart sensors

We offer precision CMOS technologies with integrated sensor modules. Small-signal conditioning can be combined with embedded controllers for edge computing in a seamless sensor fusion architecture or just for optimizing the performance of a subsystem – be it to reduce carbon emission in integrated combustion engines or to control the environment in vehicle cockpits.

- Analog and optical interfaces for high-performance SoCs (XH018, XP018)

- High-isolation SOI with superior latch-up and EMC tolerance (XT018)

- Embedded and system-in-package MEMS technology

Automotive XPLUS service package supports IATF compliant production

For the most demanding applications in terms of robustness and reliability, we implement dedicated procedures integrated in our Quality Management System. Our goal is to ensure that the end products behave as expected under harsh conditions and for an extended lifetime.

Failure prevention is ensured through

- Stringent wafer screening

- Reliability monitoring

- Dedicated defect inspection

Continuous improvement and customer cooperation are organized around

- Wafer and product yield management

- Failure analysis

- Problem-solving methodology

Business continuity for products with long life cycles is supported through

- Data retention

- Second sourcing

High-quality design support enables robust first-time-right designs

We provide a unique technology offering for robust mixed-signal and high-voltage designs. The automotive temperature range is used for qualification, characterization and modeling of our devices and IPs, including RAMs, ROMs and non-volatile memory. Dedicated solutions are provided to allow first-time-right designs, including ESD, parasitic latch-up and reliability simulations:

- AEC-Q100 grade 0 – including 175°C – qualification

- ISO 26262 safety certification of our customers’ end products supported by our ASIL-x-ready IPs

- Flexible compiler-based memories with ECC

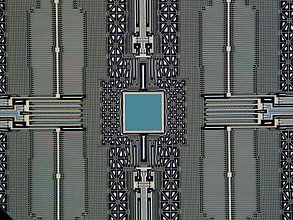

Embedded NVM IPs improve system integration

Our embedded non-volatile memory (e-NVM) IP portfolio provides a competitive edge for first-time-right designs in the automotive market. All IPs are extensively proven in the field and qualified according to automotive Grade 0 standards, ensuring that stored data are available for read-out at up to 175°C.

- Latches, fuses and one-time-programmable (OTP) memory arrays for trimming, identification, tracking or debugging purposes

- NVRAM and EEPROM for data integrity and data logging

- Embedded Flash, leveraging on our SONOS technology, specifically intended for reliable code storage for automotive applications, e.g. power train or interface with a LIN/CAN bus

Extensive tiling or IP compiler approach provide full flexibility in adapting the NVM IP to the customer design, reducing footprint and die cost.

All our e-NVM IPs come with either zero or a minimum number of mask adders to the core technology compared to other available market solutions, optimizing customer IP re-use and upgrade costs when adding NVM capability.