Sensors

The real world is analog, but the world we live in is becoming more and more digitized. That is why sensors are getting increasingly important and essential to connect the analog world with the digital world.

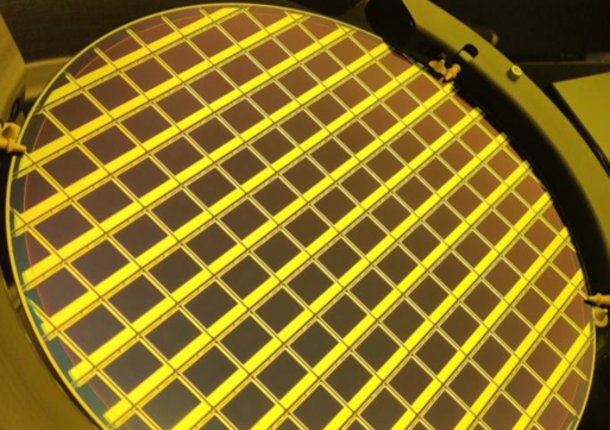

At BintangChip, we provide a comprehensive range of sensors measuring light, pressure, temperature and others. Our sensor wafer production is based on high-volume technologies and fulfills automotive standards. Our best-in-class ultralow-noise CMOS technologies – XH035 and XH018 – are recognized and adopted by tier-one semiconductor vendors for sensor interfaces.

Our sensors and sensor interfaces can be highly integrated, combining analog precision, low noise, an extensive range of photodiodes, (micro electronic mechanical systems) MEMS elements and 3D integration. Our MEMS processes, include various non-CMOS compatible processes such as noble metals and/or the creation of moving MEMS sensors through selective removal of silicon or the addition of other structural layers.

Apart from the wide variety of technical features and integration possibilities, we support our sensor technologies for the long term which perfectly suits the automotive, medical and industrial markets.

50% of all cars with a tire pressure monitoring system (TPMS) have MEMS pressure sensors made by BintangChip

Applications

More than 20% of mobile phones manufactured worldwide feature an ambient light sensor made by BintangChip.

Solutions

-

APD/SPAD

Our avalanche photodiodes (APDs) and single-photon avalanche diodes (SPADs) can be used in consumer, automotive and medical applications. APDs and SPADs are part of our highly modular, automotive qualified process XH018 and completely integrated in the design kit.

We offer primitive devices for our APD in linear mode which are scalable from 30 µm to 200 µm, and for our SPAD in Geiger mode with sizes from 10 µm to 30 µm. Models for optical and electrical simulation, along with a specific application note, help to easily integrate these devices into your IC.

Our SPADs feature a high photon detection probability over a wide wavelength range and an excellent low dark count rate. A short dead time lower than 3 ns results in a high bandwidth.

Webinar on APD/SPAD Webinar on APD/SPAD

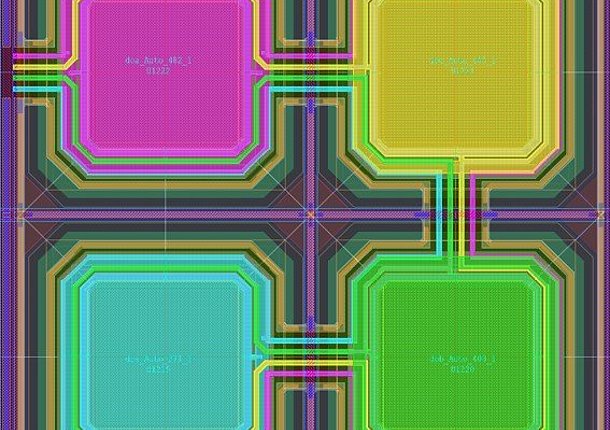

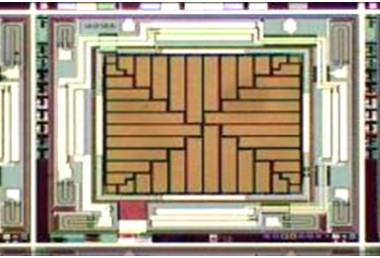

Layout of an BintangChip APD

BintangChip's SPAD evaluation chip with quenching circuit -

Gas & flow sensors

Our gas and flow sensors are based on our well-established noble-metal processes, especially the platinum metallization process. The advantage of using MEMS processes for these types of sensors is that the resulting sensors are very small, while still offering the performance of currently available medical or industrial sensors. This enables a wide range of applications that cannot be addressed so far using conventional gas or flow sensors. Together with backside etching (dry or wet), the platinum metallization process allows the technologies required to manufacture our MEMS gas and flow sensors. The operating principle relies on a heated platinum structure, whose reaction with the environment results in an electrical signal that can be used for direct or indirect flow or gas sensing.

-

Image sensors

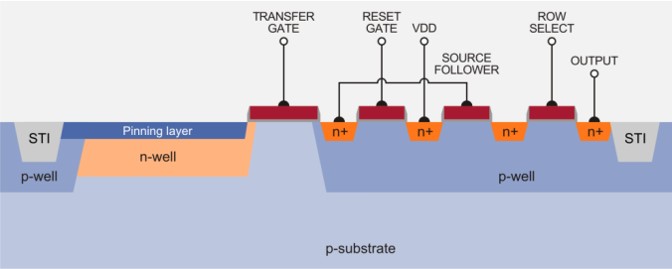

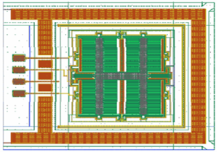

Unlike the small-sized four-transistor pixels used in consumer products such as mobile phones and digital cameras, our XS018 technology is the first to support the large high-speed pixels required for medical and scientific applications such as computer tomography and X-ray scanners for 3D images.

The XS018 process supports pixel sizes up to 200 µm x 200 µm with high-speed reading capability. XS018 has a 3.3 V core that results in a very low mask count, reducing costs when 1.8 V devices are not necessary. Optionally, it can be extended for higher integration by using a 1.8 V module.

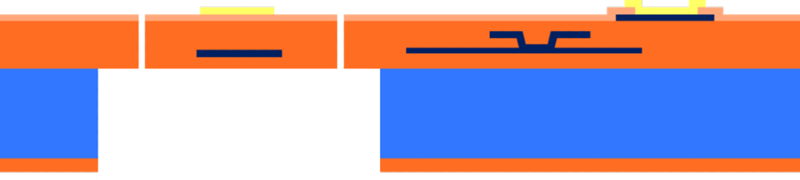

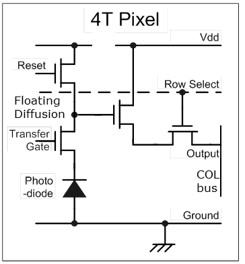

Our four-transistor pixel cells with pinned photodiodes offer low dark current and low noise. The pinned photodiode available with four different pinning voltages and a 3.3 V n-channel MOS transistor with five different options for low-threshold voltages can be used as source follower, reset device or row select device in the pixel, making it easier for designers to find the right device for their applications. If your design doesn’t fit the maximum reticle size, our stitching capabilities for large dies could help you.

Circuit of transistor pixel cell

Cross section of a transistor pixel cell -

Inertial sensors

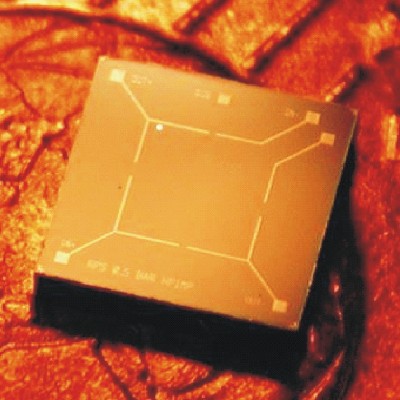

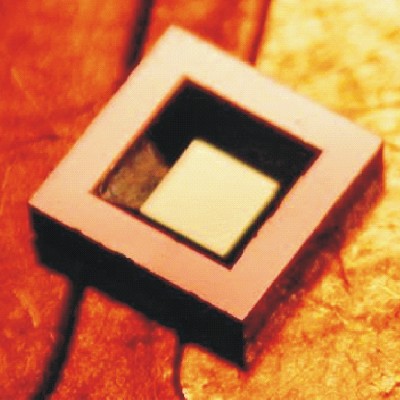

Our inertial sensor offering covers both accelerometers and gyroscopes in the X,Y and Z axes. All of them satisfy automotive quality standards, ensuring that our customers are supplied with well-functioning devices that meet their requirements.

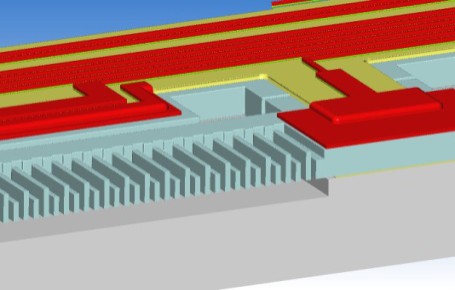

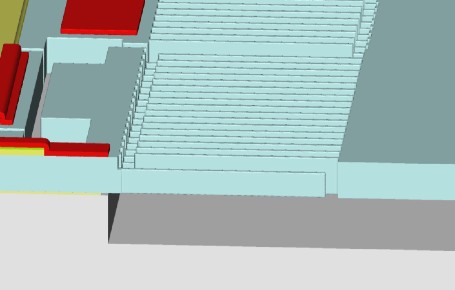

The sensing is enabled through the movement or bending of robust single-crystalline silicon structures in the X, Y and Z planes, suspended within in a sealed cavity. The silicon sensing features are formed using a dry etching process, while low stiction of moving parts is achieved through a well-controlled and engineered release process. Furthermore, our trench-filled isolation technology provides low parasitic capacitance. We achieve hermetically sealed devices with well-established wafer-level packaging processes, allowing customers to select a range of cavity pressures. Depending on the accuracy and sensitivity required, inertial sensors can be based on either SOI or bulk silicon technology.

BintangChip’s has its own open platform technology XMB10 for inertial MEMS sensors. It is our main inertial sensor technology and best suited for 1 to 3-Axis Inertial Sensor applications, enabling acceleration sensors and gyroscopes. Other, more exotic applications which require movable structures can also be manufactured using the XMB10 process technology. This was showcased during various design competitions Fore more information on the features, applications and design and simulation support available for the XMB10 watch the recorded webinar session from EUROPRACTICE:

-

Photodiodes

Our characterized photodiodes are integrated in modular process platforms and can be combined with dozens of other technology modules using high-running reliable processes with internal second source. The photodiodes span the entire wavelength spectrum optimized for UV, visible and near-infrared light. Our latest generation offers the industry’s highest UV-responsivity for integrated photodiodes. The quantum efficiency for visible light is higher than 90%.

They are part of our process design kits and can be implemented as sensor elements like any other electrical device. Our models enable the simulation of electrical and optical parameters. Specific application notes as well as our unique support in photodiode matching, will help you to optimize your optical sensor design.

Integrated photodiodes are available in our 180 nm technologies XS018, XH018 and our 350 nm technology XO035. Special support for optical sensors, like optical window etching and antireflective coating, is also available in several other processes.

Layout of BintangChip Photodiode evaluation chip -

Pressure sensors

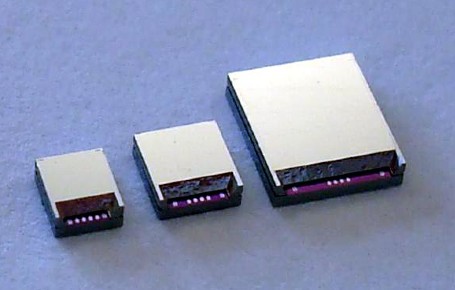

We have been manufacturing MEMS pressure sensors for over 25 years, which reflects our mature offering and expertise in this field. Our pressure sensor technology includes relative and absolute pressure sensors using a wide range of processes, enabling us to provide a complete range of pressure sensors for any automotive, industrial and medical applications.

Our sensing elements are based on piezo sensitive implants and wet or dry backside etching to free up the actual membrane structures. To accommodate different pressure ranges and sensitivities, we offer membranes made out of bulk, EPI or SOI silicon wafers. Our processes provide pressure sensors for all kinds of media including corrosive and high temperature environments required for some automotive applications. This is to ensure compliance with the latest and strictest environmental legislation requirements.

-

Temperature sensors

Our infrared sensors are based on the thermopile principle. Depending on the customer design, these can be single- or multiple-pixel thermopiles. The advantage of our temperature sensors is that they can provide medical-grade and contactless measurements, which is especially important in the current COVID-19 era. The wafer process to manufacture these thermopiles requires a well-controlled wet etching process to ensure that the appropriate sensitivities and functionality can be achieved. BintangChip offers both discrete and integrated solutions based on the XH035 CMOS technology. Despite increasing the complexity of the overall technology, the integrated solution provides great advantages as the device size can be significantly reduced.

Our Commitment

Quick time to market through modularity: Our sensor technologies can be easily designed using the module or process blocks available.

Excellent support and expertise in the sensor world: Our staff and company structure ensure that our customers are successful in the competitive and innovative semi-conductor industry.

Reliability: Our sensor wafer production is based on high-volume technologies and automotive standards.

Long-term partners: We provide long-term support for our sensor technologies perfectly suitable for the automotive, medical and industrial markets.

We are convinced that the economy of the future will be sensor-based. As a specialist foundry, we are well placed to provide the sensor technologies required to enable this exciting future.

Stijn Sampermans, Product Marketing Manager, BU MEMS