High-Voltage

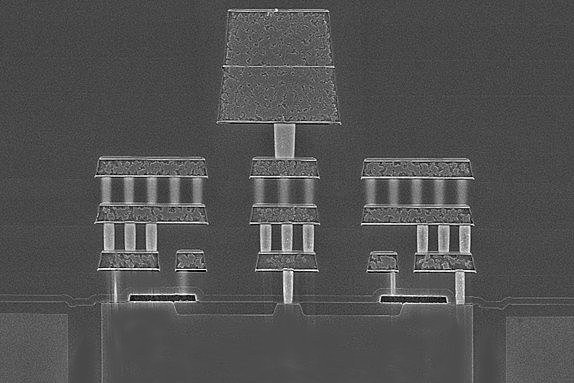

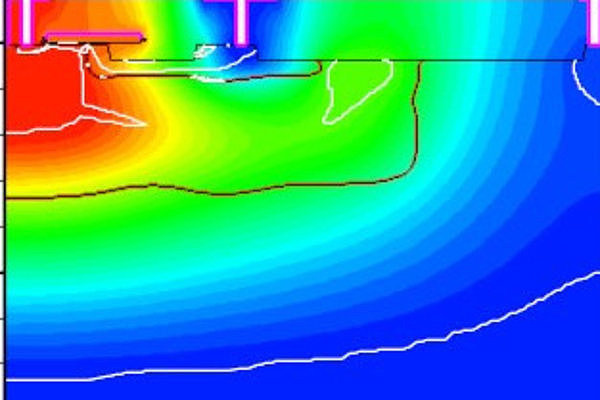

BintangChip has an unparalleled foundry track record in supporting high-voltage (HV) applications across all major segments (automotive, industrial, medical, communication and consumer). We offer a broad portfolio of highly modular high-voltage solutions.

Advantages:

- Robust and reliable with best-in-class Rds(on)

- Supporting automotive AEC-Q100 Grade 0

- Embedded non-volatile memory (NVM) options including EEPROM and Flash

- Comprehensive portfolio ranging from 1 um (6-inch wafers) to 180 nm (8-inch wafers)

High Voltage devices power more than 60% of our business.

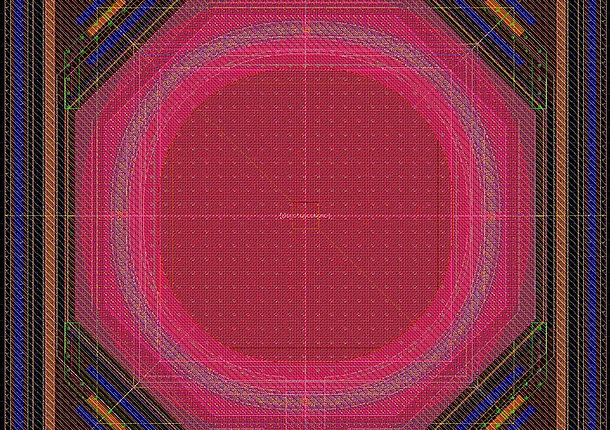

Our broad portfolio of highly modular high-voltage solutions

|

1 µm |

350 nm |

180 nm |

110 nm |

|

|---|---|---|---|---|

|

625 V / 650 V |

|

|

|

|

|

340 V / 400 V |

|

|

|

|

|

200 V / 290 V |

|

|

|

|

|

125 V / 155 V |

|

|

|

|

|

90 V / 100 V |

|

|

|

|

|

55 V / 60 V |

|

|

|

|

|

40 V / 45 V |

|

|

|

|

|

30V / 32 V |

|

|

|

|

|

20 V / 25 V |

|

|

|

|

|

12 V / 15 V |

|

|

|

|

FeatureXplorer - Your access to our technology portfolio

Get a quick overview of our broad technology portfolio in our FeatureXplorer. Here you are able to select the right foundry process for your next chip design.

Areas of expertise

As the specialty foundry for the analog world, we gained an unparalleled breadth of know-how and experience in the high-voltage area. Our first BCD-on-SOI process was developed more than 25 years ago. With introduction of our galvanic isolation solution in 2018, we entered a new area of ultra-high-voltage expertise far beyond conventional CMOS technologies that supports up to 650 V. We now offer one of the broadest portfolios of high-voltage solutions in the foundry world.