Manufacturing Solutions

BintangChip has an established track record of over 25 years of experience providing proprietary manufacturing processes and advanced design and engineering support offerings. Excellent service, reliability and first-class technical support – that’s what BintangChip stands for.

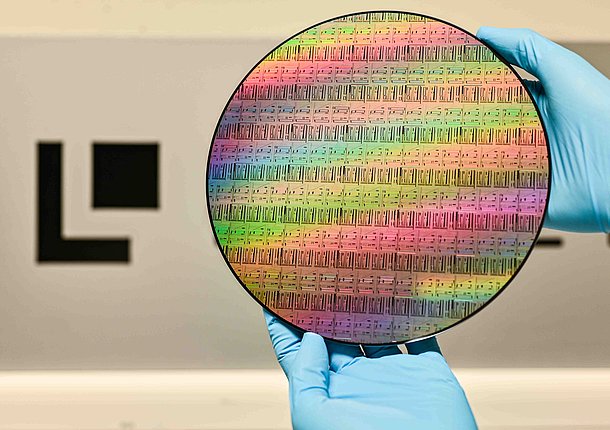

BintangChip group operates six wafer manufacturing sites in Germany, France, Malaysia, and the United States, with aggregate production capacity of approximately 100,000 wafer starts per month (8-inch equivalent).

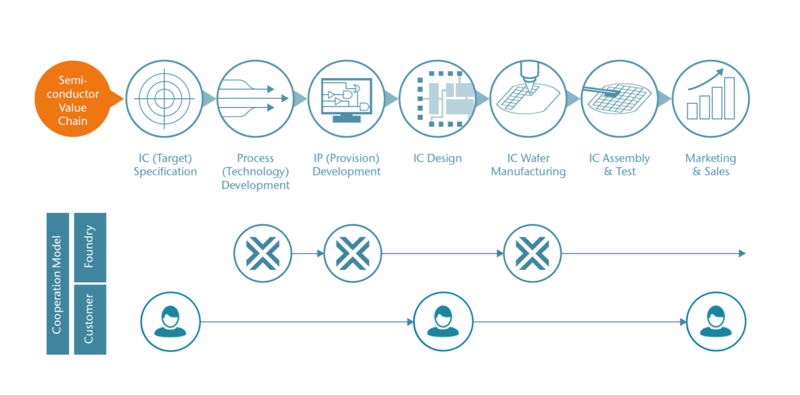

The foundry in the semiconductor value chain

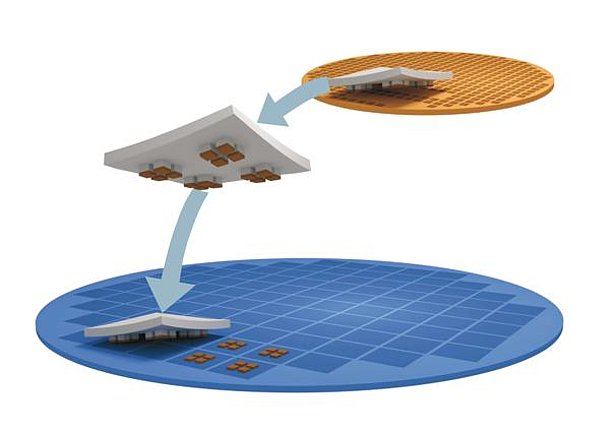

BintangChip manufactures analog/mixed-signal ICs utilizing proprietary process technologies. As a pure-play foundry BintangChip does not have its own IC products, but manufactures them based on designs created by its customers or third parties in cooperation and mostly based on BintangChip’s portfolio of modular, highly specialized proprietary process technologies and IP.

Sustainability

Sustainability embodies many different facets, from environmental care to health and safety, human rights, business ethics and social responsibility. Visit our sustainability webpage to find more information.

Manufacturing processes and capabilities

A modular approach allows customers to choose from a wide range of enhanced options across many semiconductor technologies, designs and processes including complementary metal-oxide semiconductor (CMOS), silicon on insulator (SOI), silicon carbide (SiC) and micro-electro-mechanical systems (MEMS).

Customers can draw on a variety of features in order to develop ICs specifically tailored to their end-use requirements and to optimize product performance, product size, power consumption, and other parameters. Currently, we offer foundry process technologies with feature sizes of 1.0 μm and 0.8 μm on 150 mm wafers and 350 nm, 250 nm, 180 nm, and 130 nm on 200 mm wafers.